Description

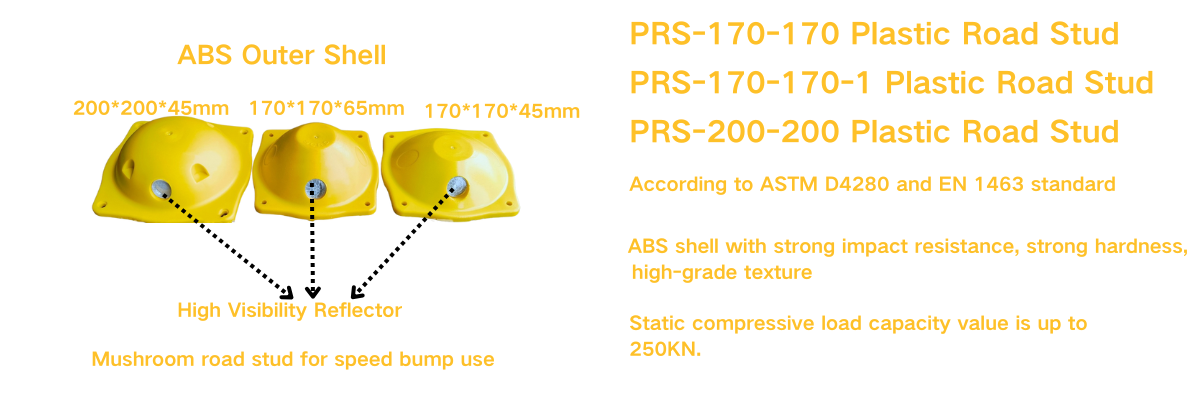

Specification of Plastic Road Studs

Retroreflective Performance of Road Studs

Reflective Brightness: The retroreflective performance of the reflective sheet of the road stud is one of the important indicators to measure whether it is qualified or not. According to the standard, the retroreflective brightness of white vertical observation should not be less than 580 mcd·lx-1.

Advantages of Road Studs

1 .Road stud shell is made of high-quality ABS raw materials with strong impact resistance, strong hardness, high-grade texture. Without using waste materials, recycled materials or added nozzle materials, to ensure the physical properties of the product.

- PMMA reflector with good reflectivity, good light transmittance, UV resistance, good resistance to climate and environmental factors.

- The road studs can pass ASTM D 4280 & EN 1463-1 standard test.

- Static compressive load capacity value is up to 160KN to 200KN.

- The visible distance of the reflective sheet is more than 500 meters.

- The waterproof level is up to IP68 standard to ensure that it can work normally in all weather conditions.

Production and Delivery of Road Studs

Applications of Road Studs

Installation of Road Studs

Without Leg Installation

- Placing and installing safety isolation facilities is of great importance. If construction is carried out on a road that has been opened to traffic, the ratio of safety personnel to installation personnel should be 1:1. For construction on a road that has not been opened to traffic, the ratio of safety personnel to installation personnel should be 1:3.

- Determine the installation location and ensure that the installation location is flat. For roads with expansion, gaps and uneven roads, the road surface should be smoothed in advance.

- Open suitable hole, ensure that the hole depth is greater than the leg depth by 1cm and the hole diameter is greater than the leg diameter by 2mm.

- Use an air gun to blow dry the holes in the pavement and clean the hole attachment locations

- Pour glue into the hole until it reaches three quarters of the way up.

- Install the road studs with glue evenly applied on the bottom into the holes, making sure the reflective sheet of the road studs faces the direction of travel.

- If too much road studs glue overflows, please wipe it clean to avoid the road studs glue sticking to the reflective sheet and affecting the use effect.

- Check two hours after installation to ensure that all road spikes are not tilted, raised or in the wrong direction.

- The isolation facility can be removed six hours after installation.

With Leg Installation

- Placing and installing safety isolation facilities is of great importance. I hope everyone will not ignore it. In addition, during the entire dynamic construction process, whether it is a new road or a road that has been opened to traffic, everyone should be in the safety facilities. If construction is carried out on a road that has been opened to traffic, the ratio of safety personnel to installation personnel should be 1:1. For construction on a road that has not been opened to traffic, the ratio of safety personnel to installation personnel should be 1:3.

- Determine the installation location and ensure that the installation location is flat. For roads with expansion, gaps and uneven roads, the road surface should be smoothed in advance.

- Clean the installation location with a brush and ensure that the installation location is dry.

- Take an appropriate amount of glue and apply it evenly on the road spikes.

- Press the road spikes tightly on the installation location to ensure the correct direction. If there is too much glue, it must be cleaned up;

- If it is a cast aluminum road spike with feet, ensure that the hole depth is greater than the nail foot depth by 1cm and the hole diameter is greater than the nail foot diameter by 2mm.

- After the installation of road studs, an inspection should be carried out within two hours to ensure that all road studs are not installed upside down, crooked or pressed.

- After the road studs have solidified for 4 hours, remove the installation isolation facilities.

Road stud installation is not a complicated matter, but there are many details to pay attention to. These details play a very important role in ensuring the quality requirements and service life of road studs.

Reviews

There are no reviews yet.